Don’t Let Gravity Filtration Bring You Down: Elevate Your Process with Crystal Filtration

- Crystal Filtration

- Sep 11, 2025

- 4 min read

In metalworking, metalworking fluids play a critical role in cooling, lubricating, and flushing away chips during machining and grinding operations. To maintain productivity, extend tool life, and ensure consistent part quality, effective filtration of these fluids is essential. One of the most cost-effective and straightforward filtration methods is gravity filtration. While gravity filters have more limited applications compared to vacuum or pressure systems, they remain a popular and economical choice where cost, footprint, and simplicity are key considerations.

Getting the Most Out of Gravity Filtration

Gravity filters function with minimal mechanical assistance, which helps keep both operating and maintenance costs low. Because they rely entirely on gravity to move fluid through the filter media, they are best suited for applications with low to moderate flow rates and where the primary goal is to remove larger particulate matter.

However, many users overlook how much performance can be improved simply by upgrading the filter media. Our sales engineers frequently encounter situations where sub-20 micron filtration is required, but the end user is still relying on basic or commodity-grade filter materials. While common options like rayon, polypropylene, and polyester are widely used, they’re not always optimized for the specific application.

In gravity filtration, disposable media is typically selected based on the manufacturer’s recommended flow rate (expressed in gallons per minute per square foot, gpm/ft²) and micron rating. When a manufacturer’s process evolves, whether by adding new tooling, modifying the application, or increasing flow rates, it’s often not feasible to change the size of the filter itself. In these cases, upgrading the filter media is the simplest and most cost-effective way to boost performance without major equipment changes.

Start Smart: How Contamination Analysis Guides Filtration Success

Effective coolant filtration begins with a clear understanding of the type and nature of contamination present in the process. In any metalworking operation, selecting the proper filter media depends on three primary factors:

Particle size and distribution

Type of contaminant (e.g., metal fines, grinding swarf, tramp oil)

Contaminant concentration levels

At Crystal Filtration, our team works directly with plant personnel to assess these variables in real-world conditions. Our engineers conduct onsite surveys, review production requirements, monitor cycle times, and collect both dirty and clean coolant samples for laboratory analysis. This data-driven approach ensures that the selected filter media is tailored to the specific demands of the application, improving filtration efficiency, coolant life, and overall system performance.

Beyond Micron Ratings: What Really Matters in Filter Media Selection

Too often, filter media is selected based solely on micron rating. While important, this should be only the starting point. Choosing the most effective media requires evaluating multiple performance factors that go beyond particle size alone:

Filtration Goals and Requirements

Start by defining your objectives. What particle size needs to be removed? What level of filtration efficiency is required? Consider the cost of inadequate filtration, including reduced tool life, poor part quality, or system failures, to help justify the right investment in higher-performing media.

Media Characteristics

Not all filter media are created equal. Evaluate options based on:

Material type

Air permeability

Particle retention efficiency

Cake formation ability

Media with optimal permeability and good cake-building characteristics can deliver longer life and reduce trial-and-error testing, ultimately minimizing downtime and maintenance.

Compatibility with Fluids and Conditions

Ensure the media can withstand the application's temperature range and chemical composition. Using the wrong media can result in premature degradation, coolant contamination, and costly unplanned failures.

Flow Rate and Pressure Drop

There’s always a tradeoff between filtration tightness and flow resistance. While tighter media can capture finer particles, it may also restrict flow and increase energy consumption. The ideal filter media will meet your cleanliness goals without introducing excessive pressure drop.

Total Operating Cost

Upfront media cost doesn’t tell the whole story. Lower-cost filters often require more frequent changes, resulting in higher labor, disposal, and downtime costs. In contrast, an engineered media, though more expensive initially, may offer two to three times the capacity and significantly lower the total cost of ownership over time.

Setting the Standard: Coolant Cleanliness and Filtration Strategy

Many small to mid-sized metalworking operations run gravity filtration systems without a defined coolant cleanliness goal, such as a parts-per-million (PPM) spec or particle count limit. Without a measurable benchmark, it’s difficult to determine if your filtration system is truly protecting your tools, equipment, and part quality.

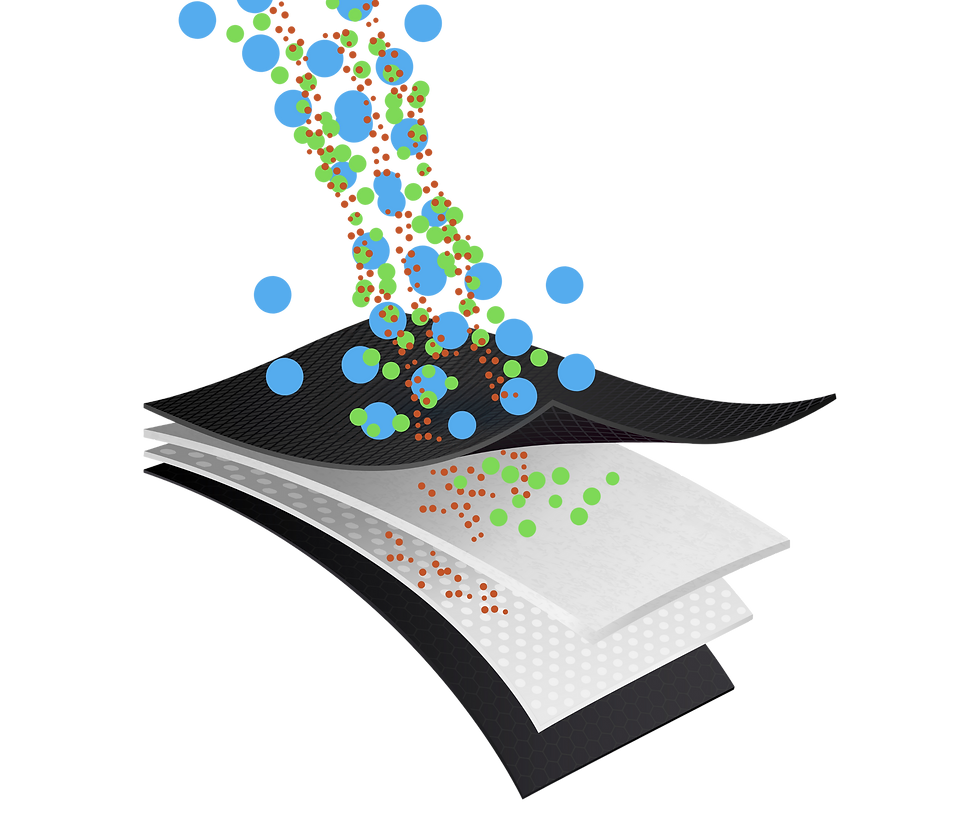

Just as important as having a target is understanding how different types of filter media affect performance. There are two primary filtration approaches:

Surface Filtration - captures particles primarily on the top layer of the media.

Depth Filtration - traps contaminants throughout the full thickness of the media, creating a more complex path that captures smaller particles and extends filter life.

Establishing a coolant cleanliness specification, and selecting filter media that balances surface and depth filtration, helps ensure longer coolant life, more consistent filtration performance, and better protection for your machining process.

Optimizing Gravity Filtration for Real-Wold Performance

Gravity filters offer a cost-effective and dependable solution for coolant filtration, but only when paired with the right filter media and strategy. To get the most out of your system, it's essential to:

Set clear coolant cleanliness standards

Understand your specific application and contamination profile

Work with a filtration partner who brings both hands-on experience and data-driven insight

At Crystal Filtration, we combine onsite process evaluations with lab-based analysis to recommend filter media that fits your operation, the first time. The result: cleaner coolant, longer equipment life, and lower total operating costs.

Ready to improve your coolant filtration?

Connect with Crystal Filtration today to discover how our custom approach leads to cleaner coolant, longer tool life, and measurable cost savings, contact us at www.crystal-filtration.com or sales@crystal-filtration.com to connect with one of our technical sales engineers.

Download PDF

.

Comments